As our world faces unprecedented challenges, the consequences of human actions are increasingly evident. Glaciers are rapidly receding, sea levels are on the incline, delicate cloud forests are withering

away, and our precious wildlife is struggling to adapt. It has become undeniable that a significant portion of the warming in the past century can be attributed to human activities, particularly the release of

heat-trapping gases during our pursuit of modern living. These gases, often referred to as greenhouse gases, have reached levels higher than those witnessed in the past 800,000 years, exacerbating the challenges we face.

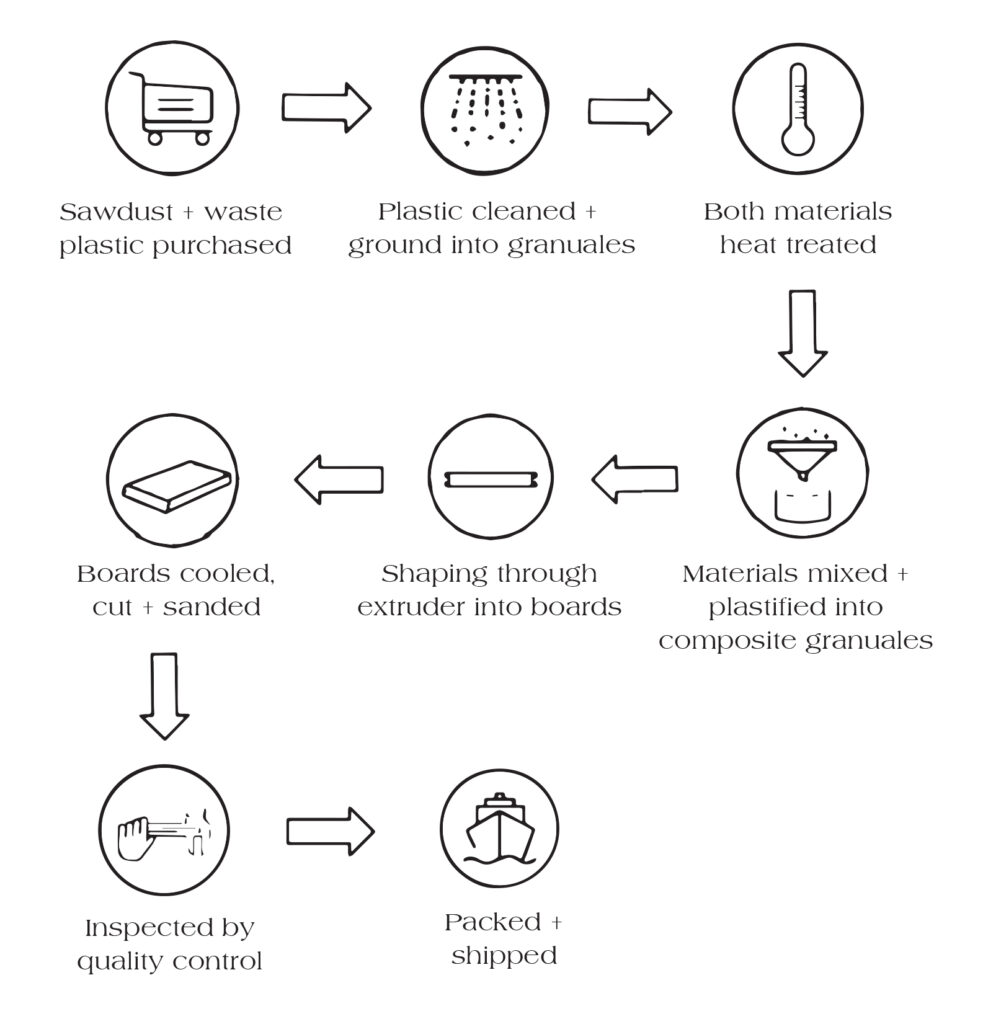

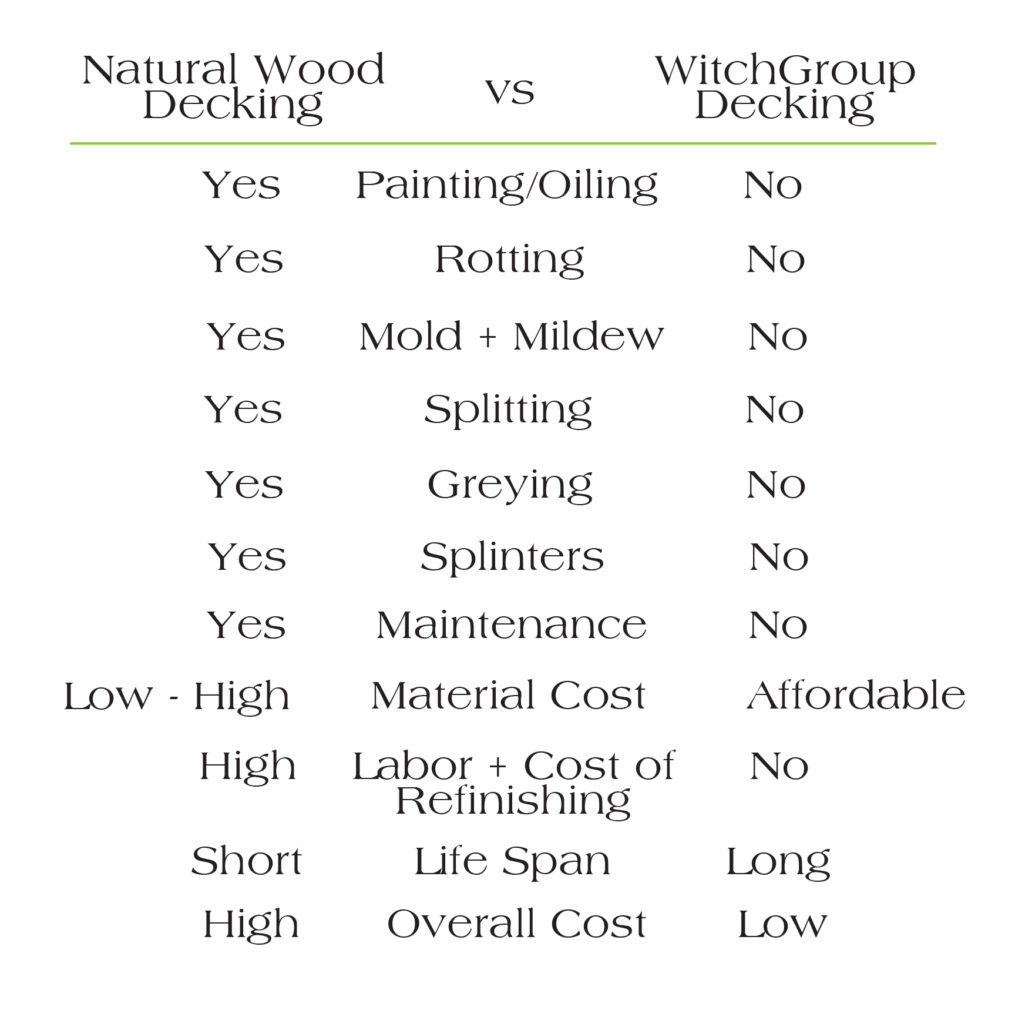

The Outdoor Look stands committed to addressing these environmental concerns. We recognize the urgency to reduce the negative impact of our choices on the planet. That’s why we’ve made it our mission to promote sustainable products that incorporate recycled plastics, such as recycled composite decking. By doing so, we aim to play our part in mitigating the environmental consequences of deforestation and plastic pollution, contributing to a healthier, more sustainable world for generations to come.

Our commitment to the environment is evident in every aspect of our decking materials. Not a single tree has ever been felled for the sole purpose of producing our recycled composite decking products. Instead, our manufacturers diligently collect surplus wood from sawmills and wood product manufacturers, repurposing it into high-quality decking boards. These boards are crafted using a remarkable ratio of up to 55% recycled wood flour.

We are equally devoted to addressing the issue of plastic waste. Our conscientious manufacturers divert wasted plastic from landfills and the ocean, forging partnerships with the plastic recycling industry. Each year, over 21,000 tons of discarded plastic find a new purpose, equivalent to the plastic content in 12.6 billion drinking water bottles. This recycled plastic is thoughtfully transformed into our innovative decking boards.

In our commitment to sustainability, our manufacturer is an integral part of the FSC-COC chain. We encourage our customers to reduce their reliance on natural wood materials by advocating the use of wood from responsibly managed sources, such as plastic recycled composite decking. By choosing composite materials, you play a vital role in protecting our environment and supporting sustainable practices.

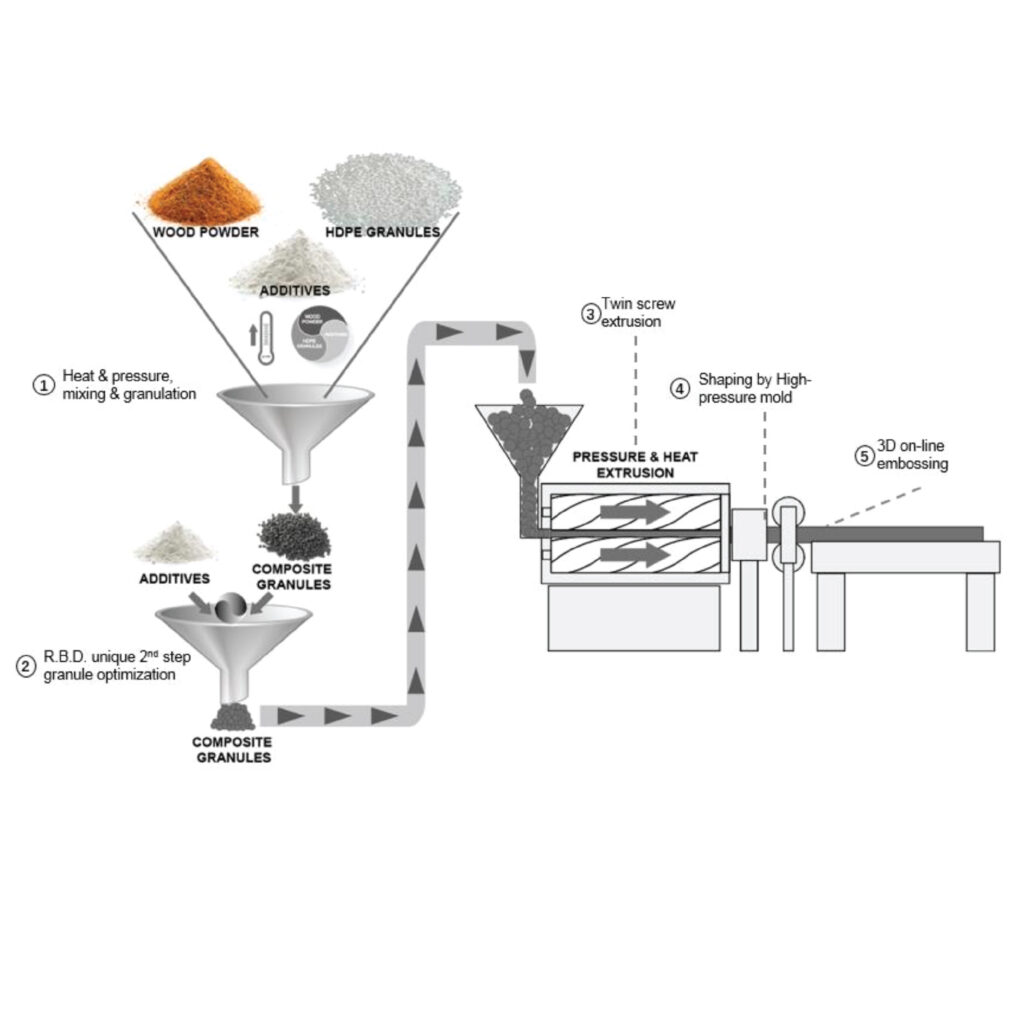

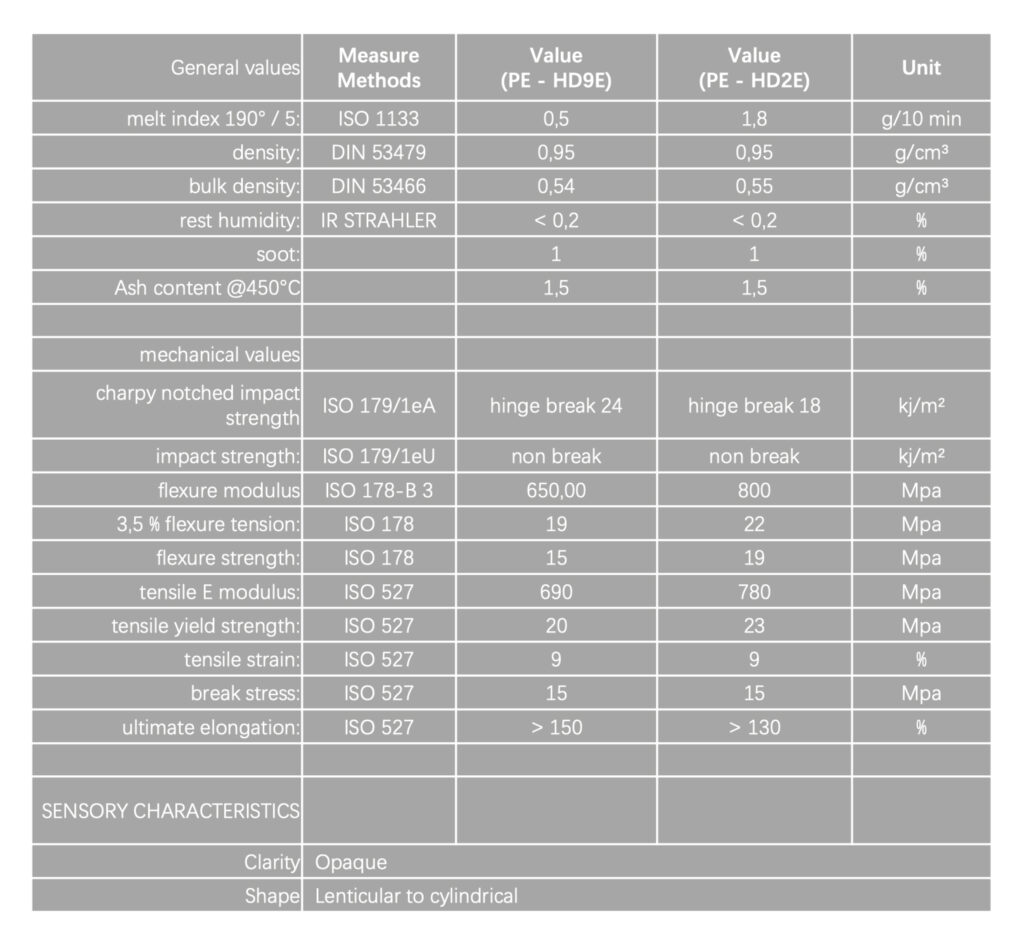

1. High-quality HDPE, sustainable wood source, and a unique composition formula with centralised HPC granule production ensure granule stability.

2. Exceptional 2nd step granule optimisation, a unique industry process, enhances material mixture consistency.

3. Twin screw extrusion (unlike some brands using single-screw) ensures thorough mixing, protecting wood flour with HDPE.

4. High-pressure molding ensures product density, squareness, straightness, and flatness, even with decreased extrusion speed. Our online embossing creates a natural 3D wood effect during production, unlike conventional methods that result in artificial-looking embossing that fades over time.

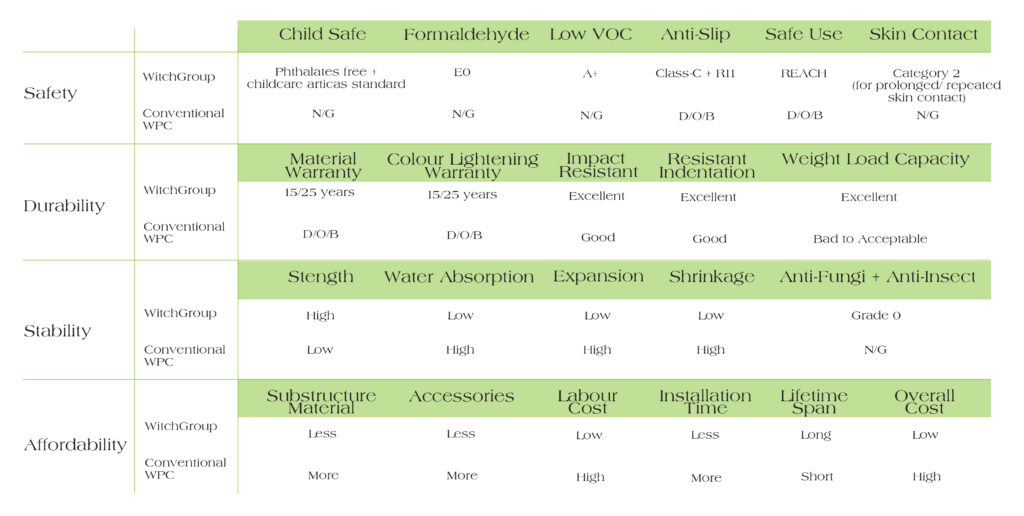

PVC-Free and Environmentally Safe: Our PVC-free HPC composite material, from sourcing to production, is dedicated to your safety and well-being. We strictly avoid the use of poorly sorted recycled plastics, including those from cable wire veneers that may retain harmful heavy metals. Our HPC products meet rigorous safety standards, are compliant with international regulations, and hold certifications verifying their safety, including REACH, low-VOC A+, POPs, PAHs-free, Phthalates-free, and E05 formaldehyde-free..

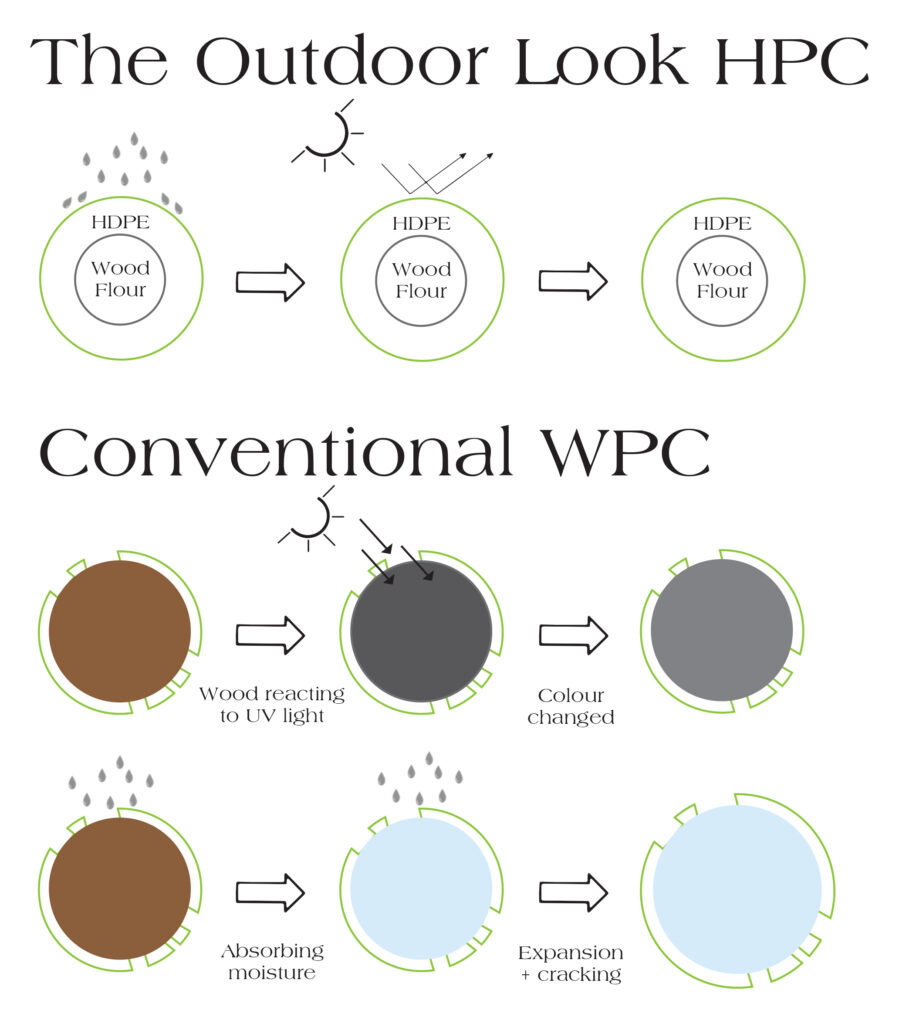

Single-Polymer Excellence: HPC stands out from most composites by exclusively utilising High Density Polyethylene (HDPE) as the single-polymer source. We avoid mixing with other polymers like polypropylene, polystyrene, or polyamide. This singular-polymer method ensures the perfect melding of plastic and wood, securing product stability and preventing material separation. Unlike LDPE, which may be cost-effective and softer, it lacks the strength and heat resistance needed for durability, a common drawback in composite materials.

High-Quality Wood Sourcing: Our HPC wood powder is sourced without lamination, ensuring no glue residues. Meeting the rigorous European formaldehyde standard E0, our HPC is committed to quality. As an FSC-COC member, we prioritise sustainable wood sources, controlling wood species and moisture levels. Our standard production employs a mesh number of 60 for wood powder, promoting even distribution in HPC granules, ensuring product stability and durability.

HDPE Standard: HDPE is the main and most important component of HPC. R-HDPE grade are reprocessed from homogeneous and clean/washed sources of high density polyethylene (HDPE).

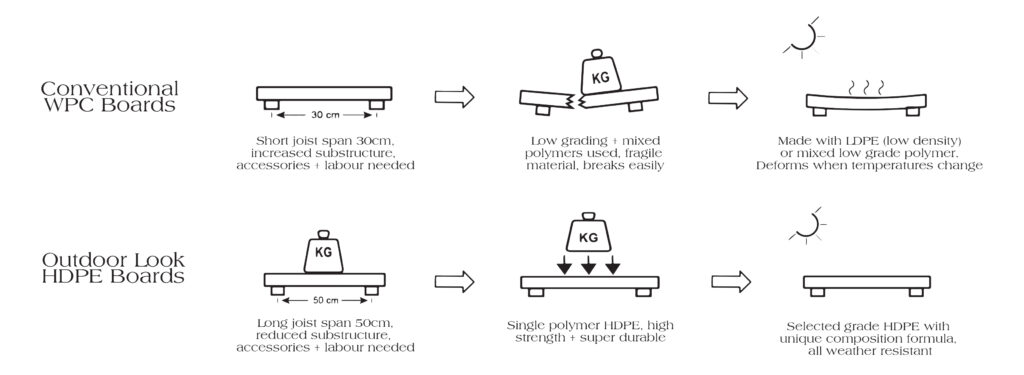

Our manufacturers are the pioneering creators of this cutting-edge, patent-pending composite innovation. The Outdoor Look stands as the exclusive decking brand to introduce a hollow decking solution capable of spanning up to 50cm during construction. This lightweight yet exceptionally robust composite product offers several advantages.

A greater span distance translates to reduced substructure materials, fewer accessories, lower labor costs, and shorter project durations. Furthermore, our product features high-grade raw materials and utilises advanced production techniques. Only top-quality composite materials can withstand the rigors of outdoor environments, ensuring resistance to deformation, colour fading, breakage, and cracking.

Maintaining the vibrant colour and safety of your decking is at the heart of our commitment at Witch Group. We understand that your outdoor living spaces are subject to relentless exposure to the sun’s harmful UV rays. To safeguard your investment, we subject our products to rigorous outdoor UV aging and resistance simulation tests, conducted in line with ISO 4892-3 standards. These tests simulate the harshest conditions, combining intense UV exposure with moisture to ensure the longevity of your deck’s colour and durability.

Beyond the aesthetics, we prioritise safety above all else. After years of unwavering dedication and extensive research, we are proud to state that all Witch Group decking products have successfully passed the stringent German DIN anti-slip test standard. This means you can enjoy your outdoor spaces with the peace of mind that your deck not only looks fantastic but also provides a secure and slip-resistant surface, protecting your loved ones and guests.

The Outdoor Look aims to make environmentally conscious decisions about the products it chooses to supply to the domestic and commercial sectors in the UK.

| Product | Delivery Cost |

|---|---|

| Samples - Royal Mail 1st (1 - 3 working days) | £0 |

| Under £100 - 3 - 5 working days | £40-60 |

| Over £100 - 5 - 7 working days | £60 - £160 Depending on location |

| Product | Delivery Cost |

|---|---|

| Samples - Royal Mail 1st (1 - 3 working days) | £0.00 |

| All Other Orders - 3 - 5 working days | £40-65 |

| Product | Delivery Cost |

|---|---|

| Samples - Royal Mail 1st (1 - 3 working days) | £0.00 |

| All Other Orders - 1 - 3 working days | £14.99 |

| Product | Delivery Cost |

|---|---|

| Artificial Plants - 1 - 3 working days | £14.99 |

| Artificial Flowers - 1 - 3 working days | £14.99 |